Kucheneswa kwefa kunoenderana nerudzi nekukora kwechinhu chiri kudhindwa.Matambudziko asina musoro anogona kukonzera matambudziko anotevera:

(1) Kana gaka racho rakakurisa, bhara redhindi redhindi rakati kurei uye hunhu hwekutsikisa hwakashata.Kana iyo gaka iri diki, kunyangwe kunaka kwekurovera kuri nani, asi kupfeka kwekufa kwakanyanya, kunoderedza zvakanyanya hupenyu hwebasa rekufa, uye nyore kukonzeresa kuputsika kwepunch.

(2) gap rakakura zvakanyanya kana diki zviri nyore kugadzira adhesion pane iyo punch zvinhu, zvichikonzera kutsika nezvinhu.Kubvisa kudiki kwakareruka kuumba vacuum pakati pepasi pepunch uye sheet simbi uye tsvina rebound.

(3) kubvumidzwa kunonzwisisika kunogona kurebesa hupenyu hwe mold, kuburitsa mhedzisiro yakanaka, kuderedza burr uye flanging, ndiro irambe yakachena, aperture inopindirana haizokwenye ndiro, kuderedza huwandu hwekukuya, chengetedza ndiro yakatwasuka, punching positioning. .

CNC punch kufa, CNC punch chishandiso, CNC kufa

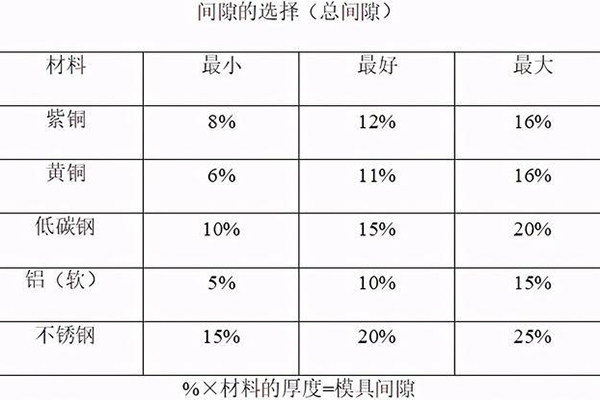

Ndokumbira utarise kune chati kuti usarudze mold clearance (iyo data iri patafura iperesenti)

(1) Kana gaka racho rakakurisa, bhara redhindi redhindi rakati kurei uye hunhu hwekutsikisa hwakashata.Kana iyo gaka iri diki, kunyangwe kunaka kwekurovera kuri nani, asi kupfeka kwekufa kwakanyanya, kunoderedza zvakanyanya hupenyu hwebasa rekufa, uye nyore kukonzeresa kuputsika kwepunch.

(2) gap rakakura zvakanyanya kana diki zviri nyore kugadzira adhesion pane iyo punch zvinhu, zvichikonzera kutsika nezvinhu.Kubvisa kudiki kwakareruka kuumba vacuum pakati pepasi pepunch uye sheet simbi uye tsvina rebound.

(3) kubvumidzwa kunonzwisisika kunogona kurebesa hupenyu hwe mold, kuburitsa mhedzisiro yakanaka, kuderedza burr uye flanging, ndiro irambe yakachena, aperture inopindirana haizokwenye ndiro, kuderedza huwandu hwekukuya, chengetedza ndiro yakatwasuka, punching positioning. .

CNC punch kufa, CNC punch chishandiso, CNC kufa

Ndokumbira utarise kune chati kuti usarudze mold clearance (iyo data iri patafura iperesenti)

Indasitiri ruzivo:

1. Nzira yekutonga sei kukanganisa kwechokwadi NC lathe

Otomatiki CNC lathe indasitiri yatarisana nedambudziko rakakura, ndiyo yepamusoro-yekupedzisira CNC muchina wekushandisa kunze kwenyika inotonga.Kubva kune data rakakodzera reCNC muchina wemidziyo yekutenga kunze kwenyika, kubva muna Mbudzi 2012, China yeCNC muchina wekushandisa kunze kwenyika yese inoratidza kudzikira, asi mutengo wekunze uri kukwira, izvo zvinogona kuratidza kuti yepamusoro-yekupedzisira CNC muchina wekushandisa kunze kwenyika unoramba uchikwira.Usataure muchina wacho pachawo, CNC muchina chishandiso ndicho chikuru chigadzirwa chemuchina wekushandisa otomatiki uye hungwaru, iyo nhanho yeCNC system yayo chiratidzo chakakosha chekuona nhanho yeatomatiki CNC lathe.Nekudaro, makumi mapfumbamwe muzana edzimba dzeCNC masisitimu anofanirwa kutengwa kunze kwenyika.

2. Ko CNC lathe inoshanda sei

CNC lathe inogona kugadzirwa nemhando mbiri dzetafura yebanga: (1) mhando yebanga tafura neiyo CNC lathe mugadziri wega kusimudzira uye dhizaini, iko kushandiswa kwekoroti imhando zvakare.Kubatsira kwerudzi urwu rwetafura yebanga mutengo wakaderera wekugadzira nekugadzira, asi kushomeka kwekuita (2) tafura yebanga repasi rose zvichibva pane zvakatemwa zvepasirese (seVDI, French Institute of Technical Engineers) uye kugadzirwa kwetafura yebanga. , CNC lathe vagadziri vanogona kusarudza uye kushongedzera zvinoenderana nebasa reCNC lathe zvigadziro.1. Unyanzvi hwekugadzira CNC lathe hunogona kuwedzerwa zvikuru mushure mekucheka tafura yekucheka yakagadzika patafura yekucheka rotary.Semuenzaniso, kushandiswa kweiyo rotary yekucheka tafura kuita radial drilling uye kucheka axial groove.2. CNC lathe CNC blade muCNC lathe kana milling kugadzira machining centre milling zvikamu, zvinofanirwa kunge zvichibva pane CNC lathe chimiro uye inogona kuiswa pahuwandu hwehuwandu hweCNC blade, hunoshanda uye hwesainzi tsvakiridzo yekugovera NC blade patafura yezvishandiso zvikamu. , uye teerera kudzivirira CNC blade mune static uye basa, The kupindira pakati NC blade uye NC lathe, NC blade uye workpiece uye yayo NC blade.

Basa racho rinogona kukamurwa kuita zvinotevera: 1. Ita nzira dzekuverenga nhamba uye matekiniki ekugadzirisa zvinoenderana nekugadzira uye kugadzirisa zvehunyanzvi zvemukati zvakatsanangurwa muchikamu chemifananidzo.Kugovera uye chirongwa chekuyerera dhizaini.2. Iyo nhamba yekudzora muchina chishandiso chirongwa chinoyerera zvinoenderana nenhamba yekudzora lathe zvinodiwa zvechirongwa chinoyerera faira fomati, uye yakadzama rekodhi munzira yekukodha pane nhare yekuchengetera midziyo, zvinoenderana nekuisa (kugadzirwa kwemaoko, kufambisa kwekombuta yemagetsi, nezvimwewo, nezvimwewo). .) nzira, zviri mukati mekugadzira uye kugadzirisa chirongwa kuyerera kune nhamba yekudzora muchina chishandiso.3. Iyo NC machine tool program inoyerera (NC code) inogamuchirwa neNC machine tool, NC code inoshandurwa kuita kana manually yakagadzirwa nesoftware programmer muCAM software, inyanzvi yedata data, kutaura kunonyanya kuoneka, nyore inonzwisiswa nekukasira nemugadziri wesoftware, asi haigone kuiswa nekukurumidza pakugadziriswa kwehardware.NC muchina chishandiso NC midziyo yakanyorwa "shanduro yeChinese" yemidziyo yekukodha, kodhi yemidziyo inoumbwa ne0 s uye 1 s yemabhinari mafaera, wozoshandura kushandura X uye Z kutungamira kusimba kwedhata chiratidzo pulse ikozvino, uye mamwe ebetsero data masaini, uye mhinduro muchimiro chekusiyanisa chiratidzo kune inobuda chiteshi cheNC muchina chishandiso, servo control system yekuita tsika.

3. Mumwaka wekunaya, maotomatiki eCNC lathes anofanira kuchengetedzwa sei

Mumwaka wekunaya kwemvura, kuchengetedza nekugadzirisa kwezvigadzirwa zvemichina zvakakosha zvikuru, nokuti mumamiriro ekunze akadaro, midziyo inowedzera kukanganisa, uye nzvimbo dzakawanda dzekumaodzanyemba kweChina dzine mvura yakawanda, uye kunyange dzimwe nzvimbo dzine mafashamo.Pano, isu tinosuma maitiro ekuchengetedza otomatiki CNC lathe mumwaka wekunaya?

Otomatiki CNC lathe ndeye chaiyo kugadzira chishandiso, ine zvinotevera zvitatu zvakakosha zvenharaunda:

(1) isa chinzvimbo che otomatiki CNC lathe kune musimboti wevibration sosi, uye haigone kuve nechiedza chezuva, mweya unodiwawo kuti uome;

(2) Zvinodiwa zvemagetsi, magetsi emagetsi anofanira kunge akagadzikana;

(3) Kupisa uye humidity zvinodiwa, tembiricha haifanire kunge iri pasi pe30 ℃, humidity haifanire kunge isingasviki 80%.Nei tichida mamiriro ezvinhu akadaro?Rega xiaobian kuti ibvise kuvhiringidzika kwauri: iyo yekutanga vibration ichakanganisa zvakananga kunaka kweiyo workpiece, nguva yakareba yekuvhenekerwa kwezuva kune kunyatso kudzora kweotomatiki CNC lathe inobatwawo;Kechipiri, kugadzikana kwemagetsi emagetsi emagetsi ndechimwe chezvinhu zvakakosha kuti ive nechokwadi chebasa rakajairwa reiyo otomatiki CNC lathe, nekuti zvikamu zveotomatiki CNC lathe zvakare zvikamu zvakaringana, kusagadzikana kwevoltage kuri nyore kukonzeresa kukuvadzwa kwezvikamu chaizvo. zvichikonzera otomatiki CNC lathe haigone kushanda nemazvo;Mushure me, tembiricha uye humidity zvakare chinhu chakakosha kuve nechokwadi chekushanda kwakajairika kweatomatiki CNC lathe zvikamu, yakanyanya tembiricha uye humidity zvinotungamira kuderedzwa kwehupenyu hwezvikamu zvehurongwa, kutadza kwakawedzera, uye kunyange kuita guruva chisungo pabhodhi redunhu, zvichikonzera dunhu pfupi.

Nyatsoteerera kodhi yemagetsi

1. The automatic CNC lathe inofanira kunyatsodiwa kuti iwane pasi, uye kushandiswa kwetatu-core power plug, kuderedza electrostatic interference, kunatsiridza kugadzikana kwemuchina uye kuchengetedzwa kwemushandisi.Muzhizha, nekuda kwekushandisa simba rakawandisa uye mwaka wekunaya kwemvura, panowanzove nekusagadzikana kwemagetsi mutsetse wemagetsi, nezvimwewo, zvichikonzera kukundikana, uye kunyange kupisa mutyairi uye zvimwe zvikamu.Inokurudzirwa kutenga voltage regulator yemuenzaniso unoenderana.

2. Kuvandudza CNC otomatiki kushandiswa kweCNC lathe, CNC nhamba yekudzora lathe kana kumhanya chiyero chisina kukwirira, mukuwedzera kumari, mhedzisiro yacho yaive shoma pane kubereka, asiwo kunetseka nezve chinhu inguva yewaranti, nekuti CNC otomatiki CNC. lathe midziyo ine waranti nguva, mushandisi anofanirwa kushandisa muchina munguva ino, iyo yakatetepa yakafumurwa nekukurumidza sezvinobvira, Kuraswa pasi pewaranti.Kana ikasashandiswa kwenguva yakareba, kuparara kana kukuvadzwa kwezvinhu zvemagetsi zvinogona kukurumidza kukurumidza nekuda kwekunyorova uye zvimwe zvikonzero.Kunyanya munguva yekunaya, unodawo kumhanyisa muchina nemazvo.

3. CNC otomatiki CNC lathe inofanira kushandiswa munzvimbo yakanaka nekuti mhepo ine mwando mumwaka wekunaya.Zviri nyore kuve munyoro mumhepo ine mwando uye kutadza.Uye teerera kune ruzivo kubasa, saka chenjera kuti usaunza maamburera kunzvimbo yekugadzira, shandura shangu, nezvimwe.

4. Ndezvipi zvikamu zvakakosha zve otomatiki CNC lathe machini

1, Automatic CNC lathe spindle bearing box: machining centre spindle inotakura bhokisi rakagadziriswa kumusoro kuruboshwe kwemubhedha.Iyo inofambisa inotenderera inotenderera yekufamba kwemota kune spindle inotakura, uye inosundidzira iyo workpiece kuti itenderere pamwechete zvinoenderana negadziriso.Nekuchinja iyo rocker chinzvimbo pabhokisi, iyo spindle inotakura inogona kuwana akasiyana eyekumhanya mareshiyo ezvakanaka uye kumashure.

2, Bhokisi rekushandisa: bhokisi rekushandisa renzvimbo yekugadzira rakagadziriswa kuruboshwe kumberi uye pasi pemubhedha.Zvinoenderana nevhiri rakarembera, kutenderera kusimba kwekufamba kweiyo spindle bearing kunoendeswa kune bhora screw kana light screw.Shandura nzvimbo yerocker pabhokisi, inogona kushandura chiyero chekumhanya chebhora screw kana light screw, uye wozozadzisa chinangwa chekuchinja mazino kana kukurumidza kucheka.

3, Siraidhi bhodhi bhokisi: Siraidhi bhodhi bhokisi rakaiswa kunze kwechigaro chemubhedha, nechigaro chemubhedha pamwe chete pamubhedha muviri slide njanji yekufamba kwakamira kwakadzokororwa.Zvinoenderana nazvo bhora sikuruu kana kuti light bar rotation fitness muchigaro chemubhedha, kaviri akamonywa ndiro inofamba nebanga kusimba.Chikamu che rocker pabhokisi rekushandura chinogona kushandisa lathe's vertical or horizontal fitness movement (kurongeka kwekufamba, kutanga kana kumira).

4. Side rack: Side rack yakaiswa kune rumwe rutivi rworuboshwe rwemubhedha.Iyo yakashongedzerwa neinochinjika yekufambisa giya (vhiri rinorembera), iro rinoendesa kutenderera kusimba kwekufamba kweiyo spindle inotakura kubhokisi rekushandisa.Gadzirisa giya rekutapurirana pareki yevhiri rakarembera uye shandira pamwe nebhokisi rekucheka kune tambo dzeguyo dzine kurira kwakasiyana.

5, Tafura yebanga: tafura yebanga yakagadziriswa mudiki dhizaini, inoshandiswa kune zvombo uye midziyo lathe chishandiso.

6, Precision CNC lathe pallet: pallet inosanganisira chigaro chemubhedha, kaviri warping plate, vhiri uye diki kaviri warping ndiro zvikamu zvina.Chisharo chemubhedha chakaiswa pamasiraidhi njanji kunze kwemuviri wemubhedha uye inogona kutamiswa yakatwasuka padivi pemasiraidhi emuviri wemubhedha.Iyo kaviri warping plate inogona kufamba yakachinjika ichitevedza dovetail slide njanji kumucheto kwekumusoro kwechigaro chemubhedha;Iyo diki kaviri warping plate inokwanisa kufamba yakatwasuka ichitevedza dovetail slide njanji kumusoro kwevhiri.Mushure mekunge vhiri ratenderera kune imwe Angle yekuona, iyo diki kaviri warping ndiro inogona kusunda banga kuti rifambe diagonally, iro rinoshandiswa kukuya mapfupi emukati uye ekunze conical nzvimbo.

7, Lathe chishandiso kuzorora: chigaro chemuswe chinoiswa pamubhedha boka remuviri slide njanji, uye inogona kutamiswa yakatwasuka pamubhedha wemuviri slide njanji.Iyo cone gomba reiyo sleeve yakatarwa pane lathe mudziyo inobata inogona kuisirwa, twist drill, reamer, tap uye mamwe mapanga uye zvishongedzo, zvinoshandiswa kutsigira chigadzirwa workpiece, kudhirowa, kufinha, kubaya uye zvichingodaro.

8, Muviri wemubhedha: muviri wemubhedha ndiyo hwaro hweCNC lathe rutsigiro.Iyo inogadziriswa kuruboshwe uye kurudyi makumbo emubhedha, anoshandiswa kutsigira zvakakosha zvikamu zvedivi relathe, uye kuita kuti varambe vakaoma hama chinzvimbo mubasa.Mapoka maviri emasiraidhi enjanji pamuviri wemubhedha anopa kutungamira kwekufamba kwakamira kwechigaro chemubhedha uye lathe chishandiso kuzorora.

9, Bhora screw: bhora screw kiyi yekugaya shinda, ndeimwe yeakakosha zvikamu zvemupendero welathe.Kuti ugare uchichengetedza iko kurongeka kwebhora screw, kazhinji hazvifanirwe kushandisa bhora screw kune otomatiki cutting.ng centre?

Nguva yekutumira: Aug-12-2022